Giving industry a head start in choosing capture solvents

Capture it, transport it then store it in deep geology: a simple description of a far more intricate process that will enable industrialised nations to slash carbon emissions while phasing out their reliance on fossil fuels.

Different technologies exist for capturing carbon dioxide (CO2) from industrial waste gases, including chemical solvents, and several are already in use commercially. However, the science is complex and there are still operational and financial challenges to be met.

In order to smooth a path for capture plant operators, the LAUNCH project is developing ways to predict the behaviour of capture solvents, under varied conditions, and identifying how to control it.

Indira Mann (SCCS) spoke to the scientists involved in these studies, which aim to help project developers select the right tools for the job.

What is solvent degradation and why is it a problem for CO2 capture operations?

Hanna Knuutila, NTNU (WP3 Lead)

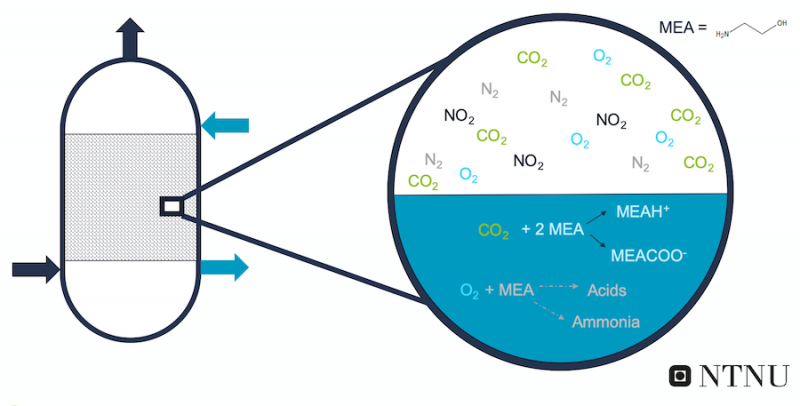

When using aqueous amine solvents – the type we are focusing on in our research – for carbon capture, the CO2 moves from gas to liquid phase, where it reacts with the solvent. The application of heat reverses that reaction and releases the CO2; pure CO2 is produced for storage and the recovered solvent can be used again.

However, flue gases contain other gas compounds, which vary widely depending on the industrial process and fuel involved. Some of these compounds, typically present in small amounts, can also react with the solvent in ways that are difficult, or even impossible, to reverse. Over time, these unwanted reactions use up the solvent and prevent it from absorbing CO2.

It’s estimated that solvent degradation accounts for up to 10% of the cost of CO2 capture. It also brings operational and safety issues, such as solvent foaming and equipment corrosion, so it’s really important that we find ways to tackle this.

Who is working on this research and who will benefit from results?

Peter van Os, TNO (LAUNCH project coordinator)

Solvent degradation is still a significant barrier to commercial-scale uptake of carbon capture. Our project partners from the private sector, research institutes and universities represent the smartest brains in the world on this crucial area of research. We are confident that, when the project concludes next year, our results will be invaluable to carbon capture and storage (CCS) project developers and capture plant operators worldwide.

We have three capture pilots, or rigs, currently being used by our project partners at TNO, RWE and the University of Sheffield for running our solvent test campaigns. We’ll then use those results and rigs to develop and demonstrate our Solvent Qualification Programme. Together with the LAUNCH CO2 Degradation Database, this will give project and technology developers a reliable route to selecting or developing capture technologies for their particular set of circumstances.

What will the LAUNCH CO2 Degradation Database provide?

Andreas Grimstvedt, SINTEF (WP1 Lead)

Our unique database will share information and analytics on capture solvent degradation from the LAUNCH project’s solvent testing programme, but it will also feature datasets from bench-scale experiments and capture pilots.

We’re still in the initial development stages but the database already features existing datasets from lab-scale testing. Over the course of our project, this will be extended significantly with further data generated by the campaigns done in LAUNCH rigs and pilots. The database will serve as a tool for several activities during the project itself and will then be made public when our research wraps up.

The customised database, which will be managed by SINTEF, is based on Dataverse, an open-access web application for sharing and analysing research data. It will include several types of data, such as text, Excel files, PDFs and graphics.

How does your predictive modelling support other project outputs?

Tanya Srivastava, TNO (WP1, 2 & 4)

Degradation datasets are a goldmine of information and by analysing those from different plants, solvents and flue gas sources, we will better understand solvent behaviour. For example, modelling can help us identify trends or sharp changes in the behaviour of the solvent. As a result, we should be able to predict – and therefore manage – this behaviour under a variety of conditions.

It’s essential that capture solvents are used and trusted by commercial operators. They want operational stability and minimal cost penalty. Our predictive modelling forms part of the LAUNCH Solvent Qualification Programme which, when fully demonstrated, will support operators in their choice of technology.

Our ultimate goal is to use the learning from LAUNCH to be able to develop the optimal solvent management strategy, which may differ depending on the capture plant design, the flue gases and the solvent used.

At TNO, we’ve been testing our patented solvent management technique, DORA – or Dissolved Oxygen Removal Apparatus – which removes oxygen from the solvent. And we’ve been able to show that this can be an effective management strategy. Oxygen is the main cause of solvent degradation and, therefore, by removing it we mitigate all the connected problems – not only the solvent loss itself but also foaming and corrosion.

What other results from LAUNCH are proving thought-provoking?

Juliana Monteiro, TNO (WP2 Lead)

Our minds and hearts are focused on predicting degradation because that will guide the management strategies that operators need. But there are still questions we need answers to. For example, to some extent we can understand why results would differ between pilot plants, but why do we see differences between campaigns run at the same pilot plant? They don’t always come to the same conclusions.

We want to be able to use predictive modelling to explain the variations between pilots and campaigns. That means that all the data needs to be available for us to do that kind of analysis. And that’s where the degradation database will pay off.

In our work on LAUNCH so far, it’s become clear that not every pilot campaign yields a useful degradation dataset. It’s really important to draw data from undisturbed operations as much as possible and in commercial operations, where there isn’t so much playing around with the parameters.

Ideally, datasets should mimic commercial operations in order to guide solvent application in the real world. RWE’s 18-month CESAR-1 solvent testing campaign at their Niederaussem capture plant in Germany is a perfect example of that. Our ambition is to understand, predict and, finally, control degradation.

If you missed the webinar LAUNCH CO2 Degradation Database – collecting datasets for solvent R&D watch the recording here.

Top graphic: MEA solvent reacts with carbon dioxide (CO2) in a capture tower, a reaction that can be reversed. Unwanted reactions with oxygen (O2) produce degradation compounds, such as acids and ammonia, reducing the solvent’s capacity to capture CO2. Credit: Hanna Knuutila/NTNU

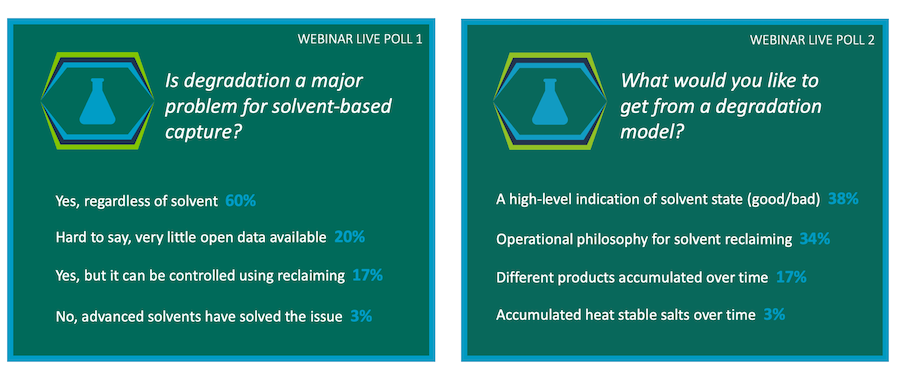

Bottom graphic: Results from two live audience polls conducted during the LAUNCH CO2 Degradation Database webinar. Design: Indira Mann