Ground-breaking CO2 post-combustion capture pilot plant achieves 100,000 hours in operation

Enabling optimisation of solvent use and improvement in cost-effectiveness for CO2 capture across industry

The CO2 capture plant at RWE’s Innovation Center at Niederaussem has reached a significant milestone: 100,000 hours in operation. Built in 2009, the plant captures greenhouse gases from the flue gases of the neighboring power plant – an important pioneer pilot project for development of carbon capture in Europe.

"For years, CO2 capture in Niederaussem has been an important platform for international cooperation in the further optimisation of this important climate protection technology," said Dr Lars Kulik, RWE Power board member, at this week’s ceremony to celebrate the plant’s achievement.

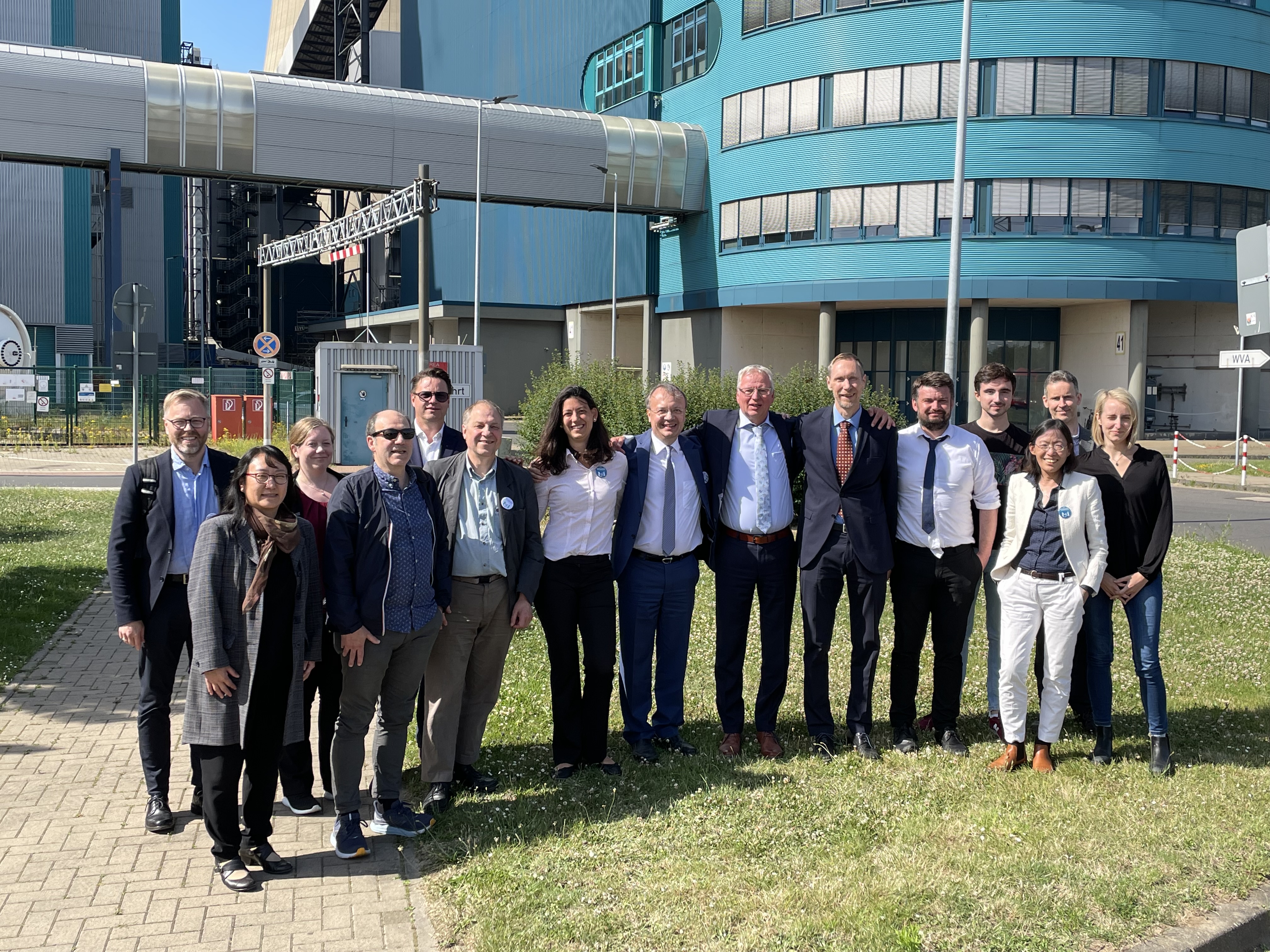

"For years, CO2 capture in Niederaussem has been an important platform for international cooperation in the further optimisation of this important climate protection technology," said Dr Lars Kulik, RWE Power board member, at this week’s ceremony to celebrate the plant’s achievement.The plant continues its important role in advancing CCUS: attending the ceremony were also some 20 researchers from the Netherlands, Norway, UK and USA. Members of the LAUNCH project, the team is examining the question: ‘How can solvent consumption be reduced in CO2 capture and thus increase its cost-effectiveness?’

This question, of reducing solvent consumption, is central to LAUNCH. Just as engine oil in a car slowly ages during operation, the CO2 scrubbing agent also loses activity over time through oxidation.

“The globally unique, long-term tests in Niederaussem are an important pillar for LAUNCH. They help experts to understand the ageing of solvents and to test innovative counter-measures,” said Tillman Bechthold, Head of Research and Development at RWE Power, describing the pilot plant’s key contribution.

The facility was originally conceived as a testing centre for post-combustion CO2 capture on a coal-fired power plant. However, with the phasing out of coal, the processes are now being developed for use on a range of industries. In parallel, RWE is also working on utilising the captured CO2 to make sustainable fuels rather than only storing it.

The Center’s recent findings are helping to simplify the design and operation of CO2 capture, for example in sewage sludge, biomass and waste incineration plants. They also serve to accelerate the development of a carbon cycle economy.

“If we couple the utilisation of CO2 and regenerative power generation, we have a closed carbon cycle for climate-neutral chemicals and fuels. This means greater security of supply, greater stability in the power grid and further significant reductions in emissions,” said RWE Power’s Dr Kulik, commenting on the far-reaching benefits of the Center’s research.

Participants also differentiated between managing fossil fuels and their emissions, with managing carbon, noting that carbon is needed to produce household goods, chemicals and fuels. We should therefore be talking about ‘defossilisation’ rather than ‘decarbonisation’, they said, as carbon will continue to be a part of our lives.